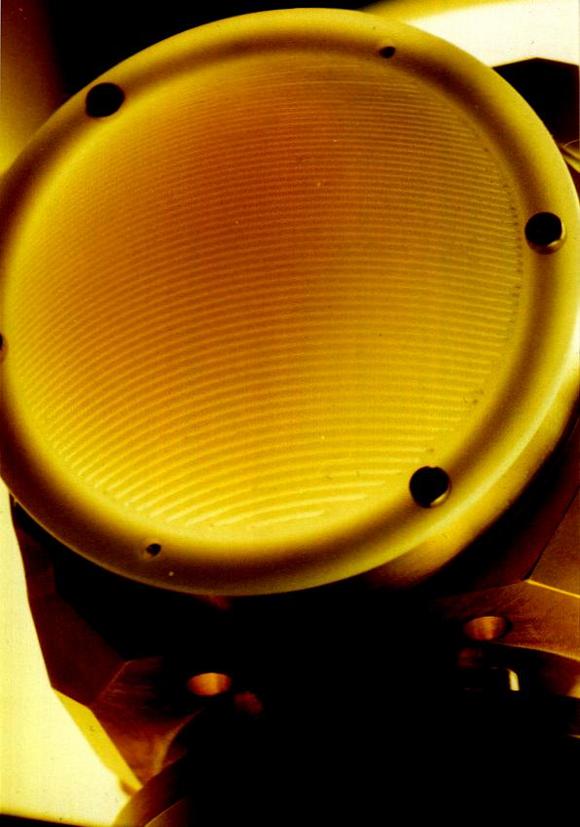

This is one of two lenses used in the 119GHz optical system. It is

made from teflon, and has grooves cut into it to reduce undesirable

reflections. A matching layer on a refracting surface is normally

made from a material which has an index of refraction exactly the

square root of that of the lens material. The matching layer can be

simulated by cutting grooves into the lens, as was done here. For

simplicity of fabrication, it would be easier to use grooves that are

concentric circles, but this gives less than optimum performance for

radiation that has a polarisation angle which is not aligned, or not

orthogonal to the matching grooves. In order to avoid loss from

misaligned grooves, the lenses for Odin were cut with linear grooves.

A Computer Numerically Controlled milling machine was programmed to

follow the surface of the lens and cut straight grooves.